Product Name:Masterbatch

Appearance: Multi Color Particles

CAS No.: 109-16-0

MOQ: 1*20'FCL

Package: 25KG PP bag, or as per your request

Description of Masterbatch:

Masterbatch is a solid or liquid additive for plastic used for coloring plastics (color masterbatch) or imparting other properties to plastics (additive masterbatch). Masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape. Masterbatch allows the processor to colour raw polymer economically during the plastics manufacturing process.

Specification of Masterbatch:

| Name | Pigments Content | Moisture | Meso-cellulite | Melting Point | Carrier |

| color masterbatch | 20-75% | <0.01% | >25 | 180-300 | PE/PP/PET etc. |

Application of Masterbatch:

Widely used in polyethylene, polypropylene, polystyrene, ABS, nylon, PC, PMMA, PET and other resins to produce colorful fibers, clothing, daily plastics, wires and cables, household appliances, agricultural films, automotive Accessories, health care equipment and other products.

Classified by carrier: PE masterbatch, PP masterbatch, ABS masterbatch, PVC masterbatch, EVA masterbatch, etc.

Classified by color: such as color masterbatch, black masterbatch, white masterbatch, etc.

Classification by function: masterbatch for coloring; anti-aging masterbatch, antistatic masterbatch, antibacterial masterbatch, flame retardant masterbatch and other functional masterbatch

Each variety can be divided into different grades:

1. Advanced injection masterbatch: used for cosmetic packaging boxes, toys, electrical appliance casings and other high-end products.

2. Ordinary injection color: used for general daily plastic products, industrial containers, etc.

3. Advanced blown film masterbatch: used for blow molding coloring of ultra-thin products.

4. Ordinary blown film masterbatch: used for blow molding coloring of general packaging bags and woven bags

5. Spinning masterbatch: used for spinning and coloring textile fibers. The masterbatch has fine pigment particles, high concentration, strong tinting power, and good heat resistance and light resistance.

6. Low-grade masterbatch: used to manufacture low-grade products that do not have high requirements on color quality, such as trash cans, low-grade containers, etc.

7. Special color masterbatch: It is a color masterbatch made according to the plastic type specified by the user and using the same plastic as the carrier. For example, PP masterbatch and ABS masterbatch use PP and ABS as carriers respectively.

8: Universal masterbatch: A certain resin (often low-melting point PE) is also used as a carrier, but it can be applied to the coloring of other resins besides its carrier resin.

Package of Masterbatch:

25KG PP bag, or as per your request

Storage:

Kept in a light-proof,well-closed,cool and dry place.

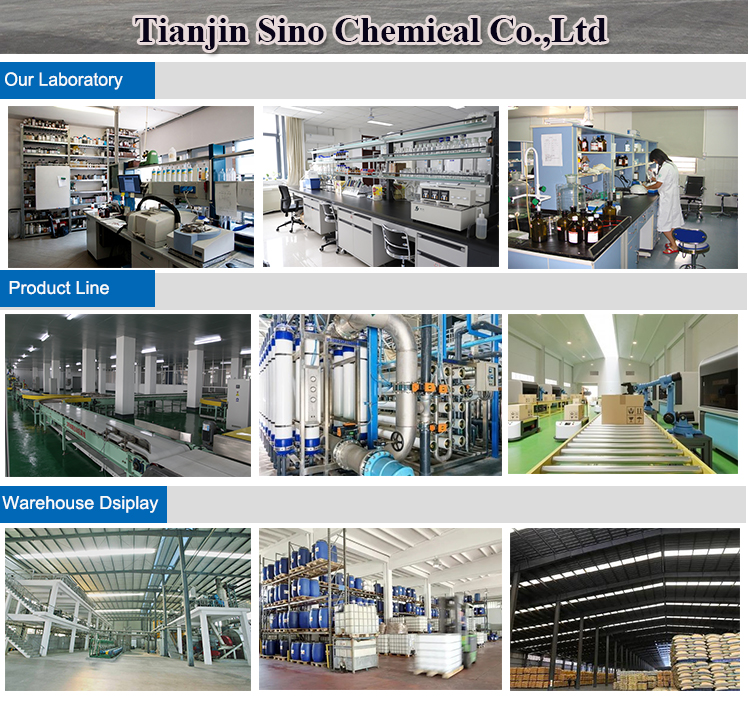

Our Factory:

Certificate: