Product Name:Polypropylene/PP

Appearance: White granular

CAS No.: 9003-07-0

MOQ: 1*20'FCL

Package: 25kg/bag or as per your request

Description of Polypropylene/PP:

Polypropylene is a high-performance thermoplastic synthetic resin, which is a colorless and translucent thermoplastic lightweight general-purpose plastic. It has chemical resistance, heat resistance, electrical insulation, high-strength mechanical properties, and good high wear resistance processing performance.

Main Characteristic of PP Material Raw PP Polypropylene Plastic:

1. Use glass fiber or mineral reinforced polypropylene pp polymer.

2. There is no floating fiber on the surface, and the appearance of the product is good.

3. The size is stable and the shrinkage rate is low.

4. High rigidity, high strength, high heat distortion temperature, chemical corrosion resistance.

Specification of Polypropylene/PP:

| Analysis Item | Quality Index | Test Result | Method |

| Colour particles,pcs/kg | ≤5 | 0 | |

| Big and small particles,g/kg | ≤10 | 0.3 | |

| SH/T 1541-2006 | |||

| Melt Index(2.16kg),g/10min | 33.0-41.0 | 37 | GB/T 3682-2000 |

| Tensile yield strength,Mpa | ≥29 | 33.8 | ASTM D638 |

| Flexural modulus,Gpa | ≥1.0 | 1.302 | ASTM D790 |

| Izod notched impact strength23ºC,J/m | ≥14 | 25.7 | ASTM D256 |

| Yellow index | ≤2 | -4 | ASTM E313 |

| Ash content,% | ≤0.022 | 0.0152 | GB/T 9345.1 |

Application of Polypropylene/PP:

Polypropylene PP is light, non-toxic, good in performance, and can be used for steam sterilization, with a wide range of

applications.

1.Fiber ( Carpet, Textiles, Upholstery, etc.)

2.Film ( shopping bags, casting film, multilayer film, etc.)

3.Blow Molding ( Medical & Cosmetic container, Lubricant & Paint container, etc)

4.Extrusion Molding ( Sheet, Pipe, Wire & Cable, etc.)

5.Injection Molding ( Automotive, Electronic, Construction, House wares, Furniture, Toys, etc.)

Package of Polypropylene/PP:

25kgs bag or customized packaging as your requestment

Storage:

Kept in a light-proof,well-closed,cool and dry place.

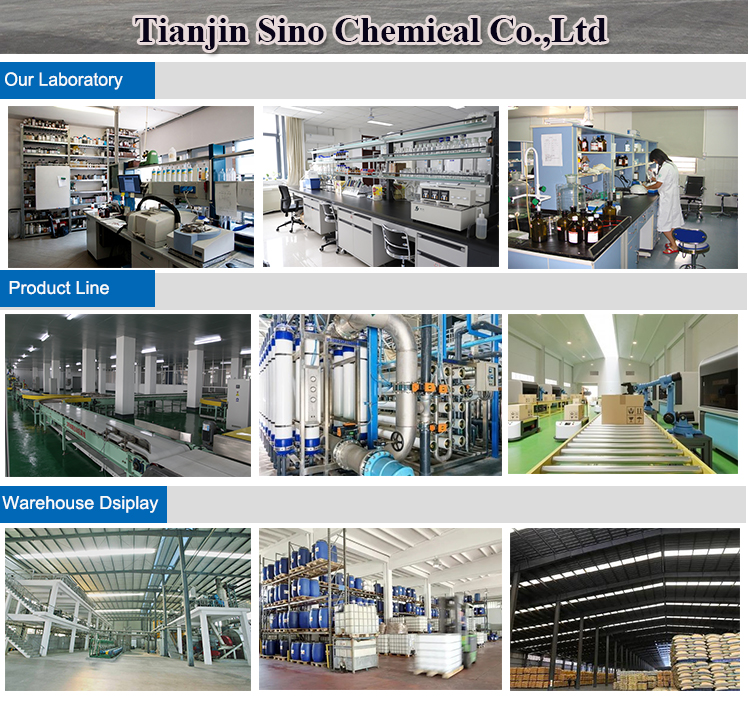

Our Factory:

Certificate: