Product Name: Phenolic Resin

Other Name:Vat blue; Dihydro, formaldehyde, phenol polymer, Paraformaldehyde

Appearance: colorless or yellowish-brown transparent in granular or powdered form

Cas No. 9003-35-4

HS:3909400000

MOQ:16MT/20'FCL

Package: 25kg bag or as per your request

CAS 9003-35-4 Phenolic Resin

Phenolic resin, originally colorless or yellowish-brown transparent in granular or powdered form. Resistance to weak acid and weak alkali, decomposition occurs in strong acid, corrosion occurs in strong alkali. Insoluble in water, soluble in acetone, alcohol and other organic solvents. It is obtained by polycondensation of phenol aldehyde or its derivatives.

Introduction of Phenolic Resin

Name: Phenolic Resin

Other Name: phenol-formaldehyde resin

Appearance: colorless or yellowish-brown transparent in granular or powdered form

CAS No.: 9003-35-4

Softening point (℃): 108-114

Residual carbon /850℃ (%):53-58

MOQ: 5 MT

Package: 25kg craft paper bag

2.Specification of Phenolic resin:

| Grade | Softening point | Free phenol | Water content | Residual carbon | Application/ |

| (℃) | (%) | (%) | /850℃ (%) | Characteristic | |

| 1 | 108-114 | 2.5-4.0 | ≤1 | 53-58 | coating and dry material |

| 2 | 108-114 | ≤4.0 | ≤1 | ≥51 | coating and dry material |

| 3 | 95-110 | ≤4.0 | ≤1 | 40-50 | modified resin, coating and dry material |

| 4 | 108-114 | 1.5-3.5 | ≤1 | 48-56 | modified resin,dry material |

| 5 | 98-105 | ≤4.5 | ≤1 | 37-42 | plug, stopper rod ,water gap, dry material , thermoplastic |

| 6 | 103-109 | 3-4.5 | ≤1 | 37-42 | plug, stopper rod ,water gap, Thermoplastic |

| 7 | 108-114 | ≤4.0 | ≤1 | ≥37 | coating and dry material Thermoplastic |

| 8 | 108-114 | 2.5-4.5 | ≤1 | ≥40 | coating and dry material, Thermoplastic |

| 10 | 101-120 | 3-4.5 | ≤1 | ——— | Thermoplastic |

| 11 | 105-113 | 2-4 | ≤1 | ≥53 | high intensity dry material |

Hot selling: Phenolic Resin 2123/2130/2402

Application of Phenolic resin

Phenolic resin is mainly used in the manufacture of various plastics, coatings, adhesives and synthetic fibers.

Compression molding powder

The production of molding powder for molded products is one of the main uses of phenolic resin. Thermoplastic phenolic resin molding powder is mainly used in the manufacture of switches, sockets, plugs and other electrical parts, daily necessities and other industrial products. Thermosetting phenolic resin molding powder is mainly used in the manufacture of high electrical insulating parts.

Phenolic glue

Thermosetting phenolic resin is also an important raw material for adhesives. The single phenolic resin is brittle and is mainly used for bonding plywood and precision casting sand.

Phenolic fibre

Mainly used as protective clothing and flame resistant fabrics or interior decoration, can also be used as insulation, heat insulation and heat insulation, filter materials, etc., can also be processed into low strength, low modulus carbon fiber, activated carbon fiber and ion exchange fiber.

Anti-corrosion material

Several forms of thermosetting phenolic resin commonly used in the field of corrosion prevention: phenolic resin coatings;

Phenolic resin FRP, phenolic resin - epoxy resin composite FRP; Phenolic resin mastic, mortar; Phenolic resin impregnated, pressed graphite products.

Thermal insulation material

It is mainly phenolic resin foam material, which can be widely used in central air conditioning system, light insulation color

steel plate, house insulation and energy reduction insulation, chemical pipeline insulation material, vehicle and ship insulation field.

Package & Storage of Petroleum Resin:

25KG bag , 16MT/20'FCL .

also be packed according to customer's needs.

Store closed containers in a cool, dry, well-ventilated area. Avoid exposure to direct sunlight.

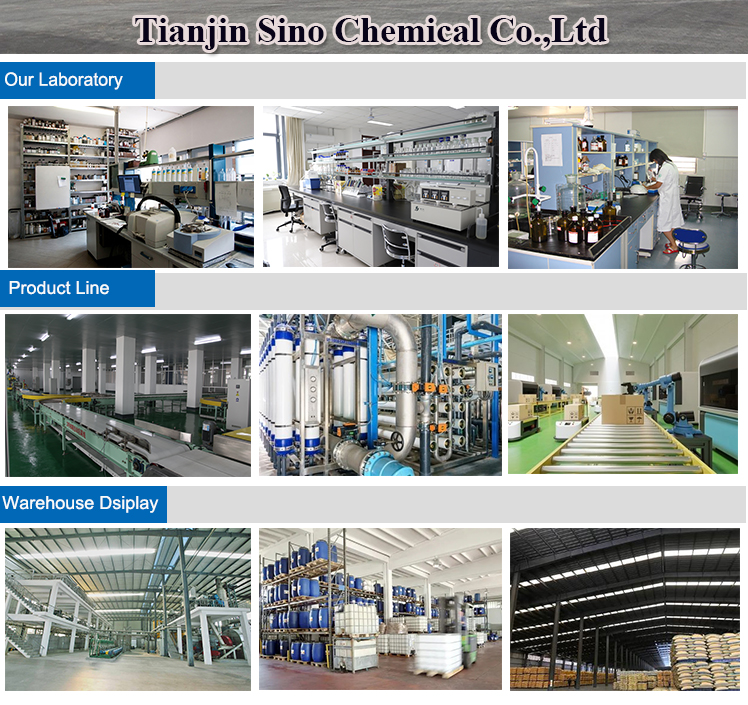

Our Factory:

Certificate: