Product Name: GLASS FIBER

HS Code: 70195900

MOQ:1*20'FCL

Package: 50KG ROLL

Description of Fiberglass:

Continuous fiber glass products, including Assembled Roving.Direct Roving, Dry Chopped Strands, Wet Chopped Strands, Flame Retardant FiberGlass, Woven Roving, Powder Chopped Strand Mat, Emulsion Chopped Strand Mat,Glass Filament Yam, Marketable Cake, Cut Strands, Texturized Roving, Milled Fiber andPiR Chopped Strands.

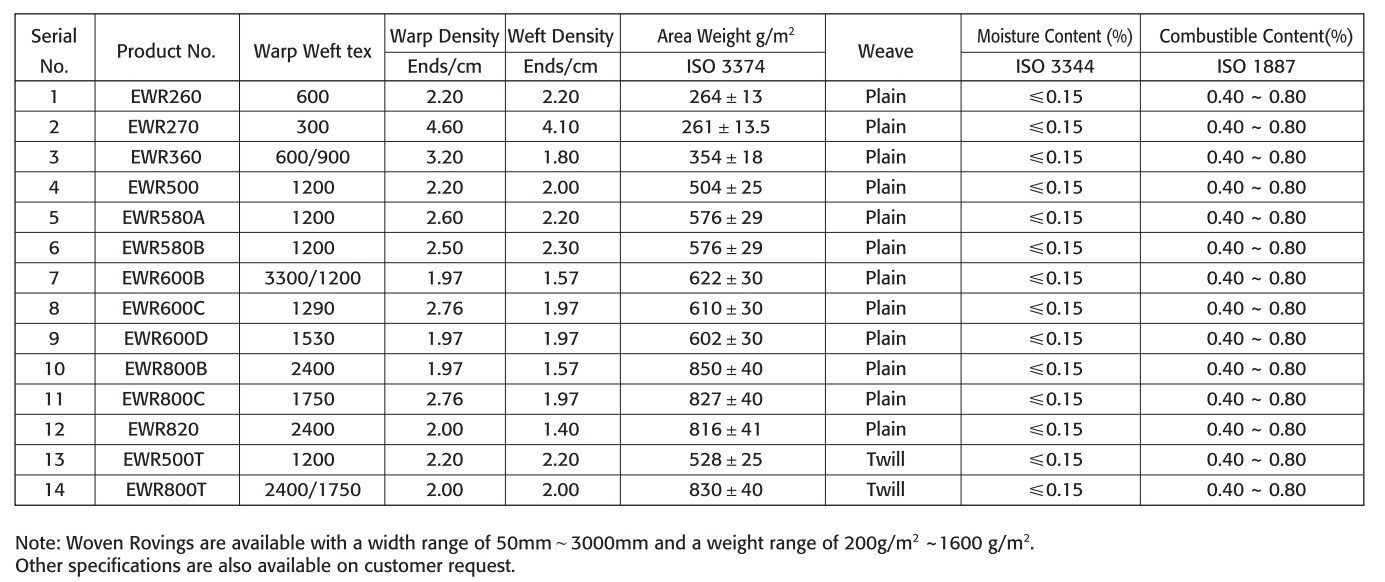

Specification of Fiberglass:

Application of Fiberglass:

E-Glass Woven Rovings are bidirectional fabric made byinterweaving direct rovings.E-Glass Woven Rovings are compatible with unsaturatedpolyester, vinyl ester, epoxy and phenolic resins.E-Glass Woven Rovings are a high-performance reinforcementwidely used in hand lay up and robot processes to manufactureboats, vessels, plane and automotive parts, furniture and sportsfacilities.

Features of Fiberglass:

© Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

© Densely aligned fibers, resulting in high dimensional stability and making handling easy

© Good moldability, fast and complete wet out in resins, resulting in high productivity

© Good mechanical properties and high strength of parts

Package of Fiberglass:

Woven Rovings are wound onto a paper tube which has an insidediameter of 89mm, and the roll has a diameter of 260mm. The roll iswrapped up with plastic film, and then packed in a cardboard box orwrapped up with kraft paper. The rolls are to be horizontally placed. Fortransportation the rolls can be loaded into a container directly or onpallets.

FIBRA DE VIDRIO MAT (EWC) 300 - 1400, 10.08MT/1*20FCL

FIBRA DE VIDRIO MAT (EWC) 225 - 1400, 8.736MT/1*20FCL

WOVEN ROVING (EWR) 600 - 1400, 17.92MT/1*20FCL

Storage

Unless otherwise specified, fiberglass products should be stored in a dry,cool and rain-proof area. The room temperature and humidity should bealways maintained at 15℃~35℃ and 35%~65% respectively.

Our Factory:

Certificate: